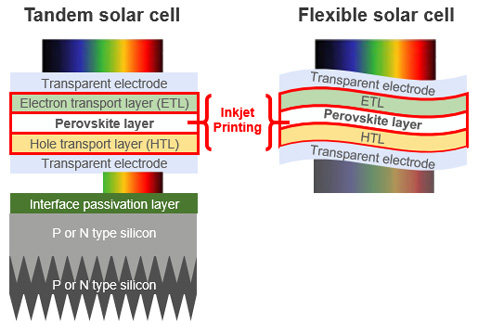

| Perovskite solar cells | Structure of perovskite solar cells |

|---|---|

|

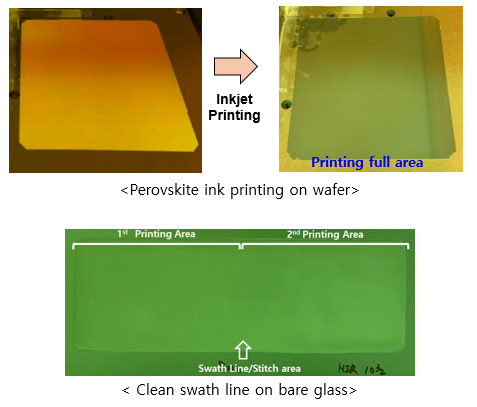

· 기존 Silicon solar cell 대비 가볍고 저렴하게 생산 가능 · 필름과 같이 유연한(Flexible) 기판에도 적용 가능 · Tandem (Silicon+Perovskite)구조로 광전변환효율 극대화 · Thickness : <1㎛ , Uniformity : <2% · 대면적 인쇄 가능 (Clean swath line)

|

|

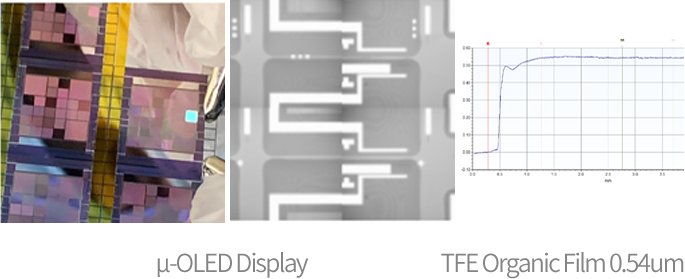

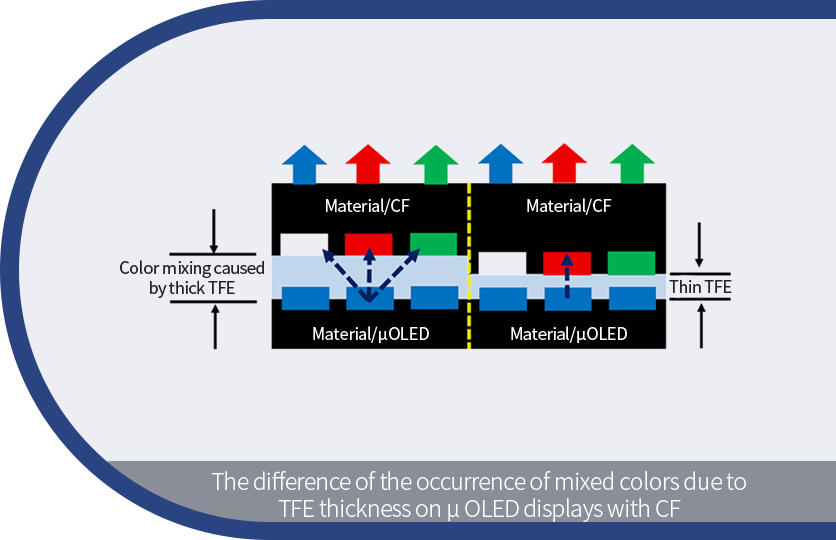

· Block with oxygen and moisture - OLED material protection

· Required <1 ㎛ thickness to prevent pixel-to-pixel light interference

· 100% Solid Contents UV- curable Organic Materials Printing

· Ensuring transparency and flexibility

· Thickness: 0.3-2 ㎛ / Uniformity < 2%

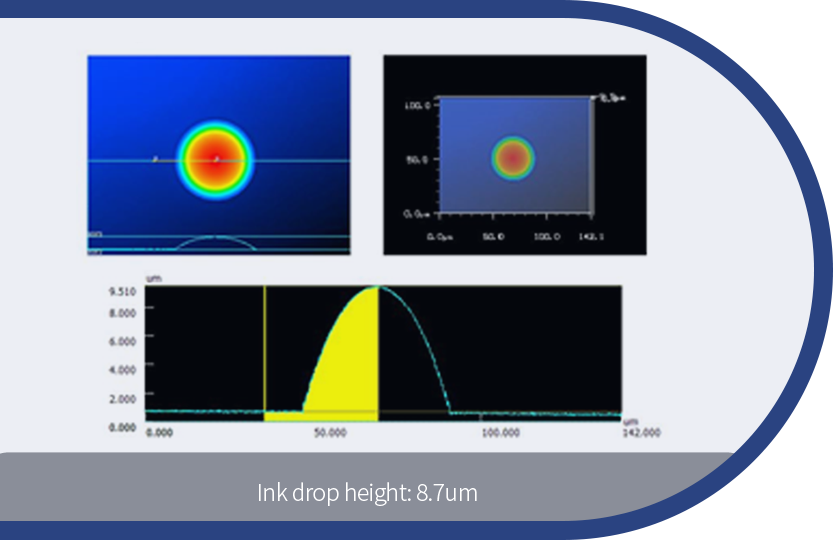

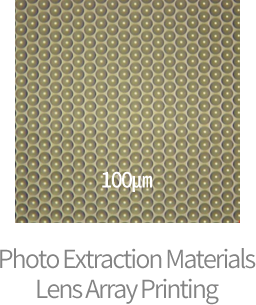

· Printing of refractive index matching material for better light extraction

· Formation of uniform film thickness and lens

· Material refractive index adjustment range: 1.4 to 1.9

· Improved light extraction (to 23%) with refractive index matching

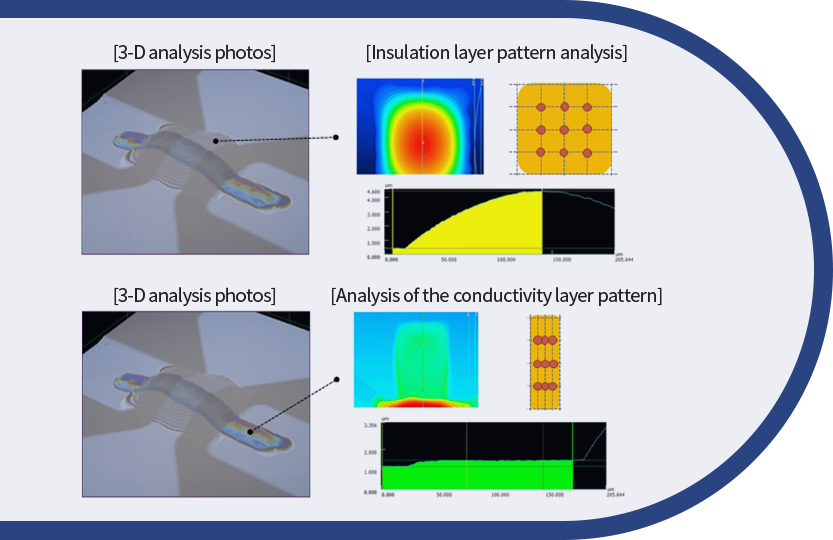

· Thin film insulation layer required for increased substrate flexibility → Low K material printing

· Thickness: 1 to 4 ㎛ / Uniformity:<2%

· 100% Solid contents Uv-curable ink printing → High permeability, Low light absorption

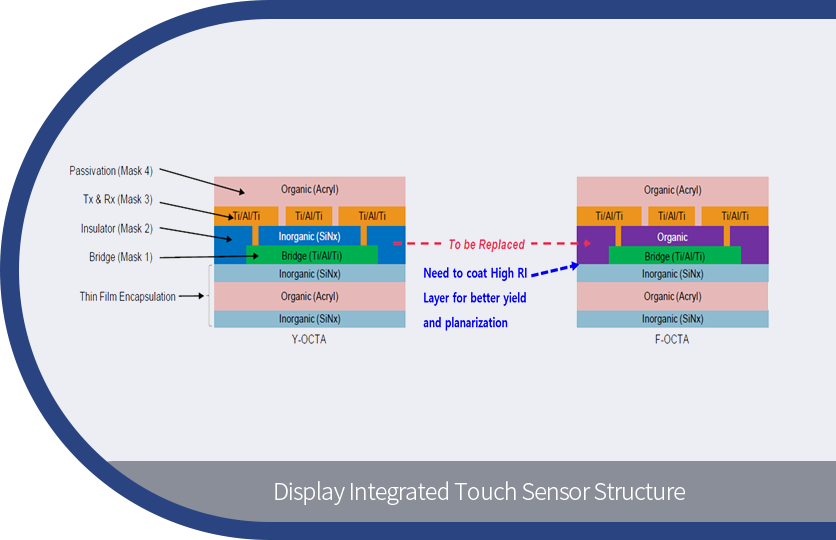

· Printing of conductive jumper after printing the isolated Bridge on the touch screen ITO pattern

· Thickness: Isolated Bridge-2 ㎛, conductive Jumper to 0.35 ㎛

· low temperature curing process

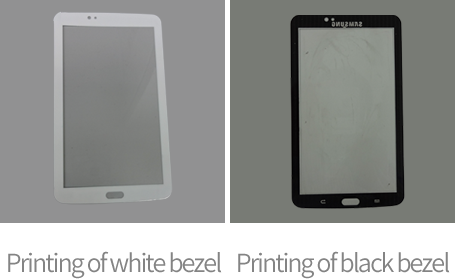

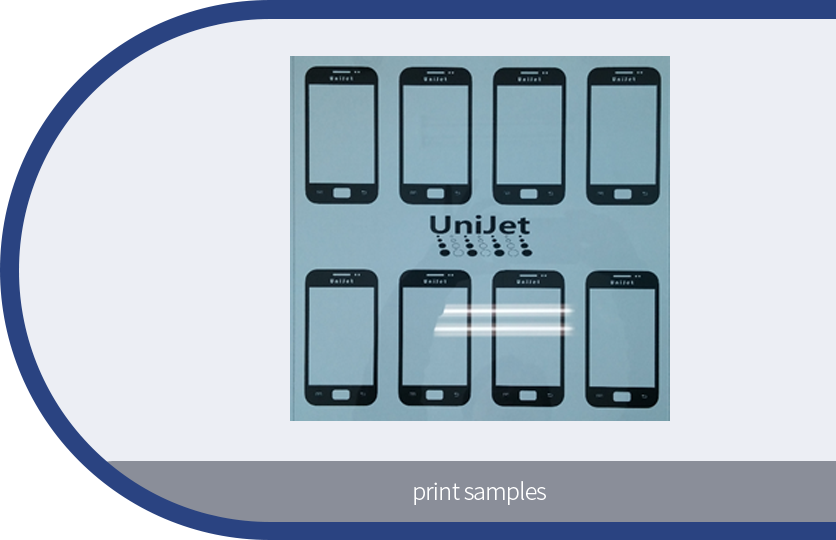

· Printing of the black and white bezel for display

· Black Bezel: Thickness 2-3 ㎛, OD>3

· White Bezel: Thickness>30㎛, Opacity>98%

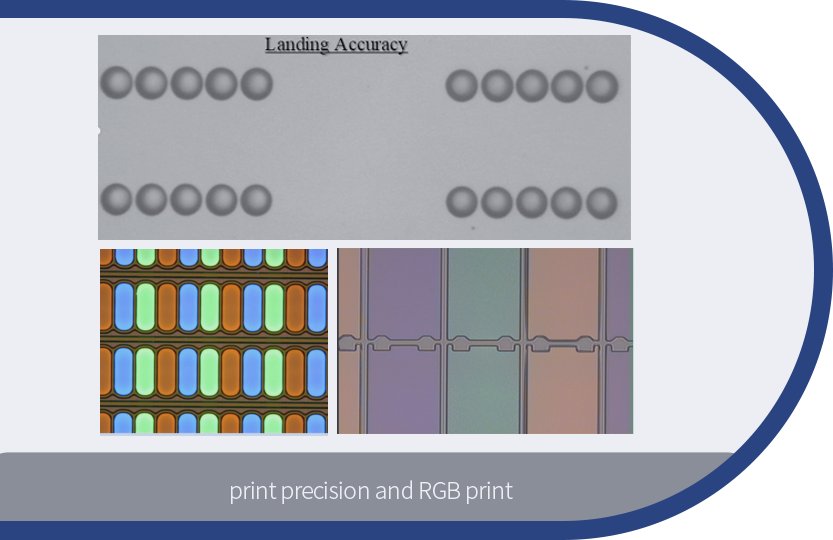

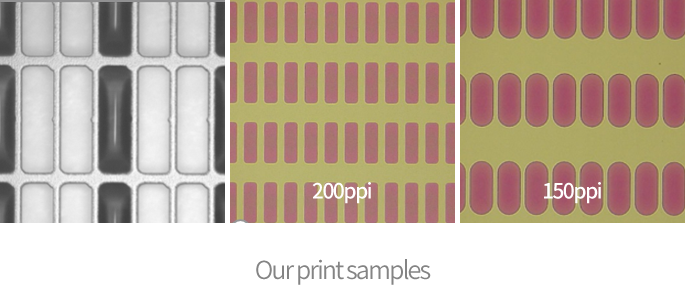

· Color Filter, Soluble OLED, PEDOT, IL, HIL, HTL, Soluble Qunatum Dot, QDCC

· Maximum pixel print resolution: To 500ppi

· 100% Solid UV ink printing

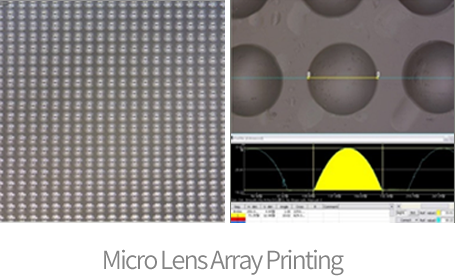

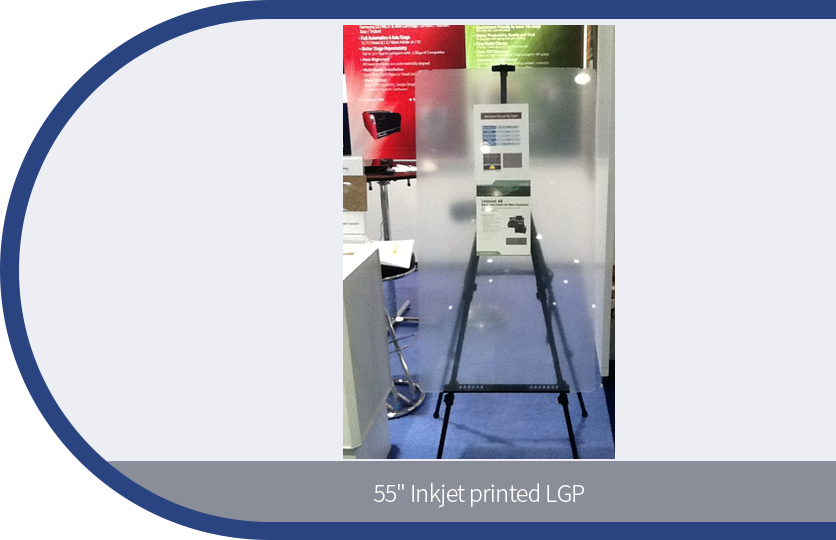

· Adjust Micro Lens size and height according to requirements

· LCD BLU, Sensor, etc.